Products

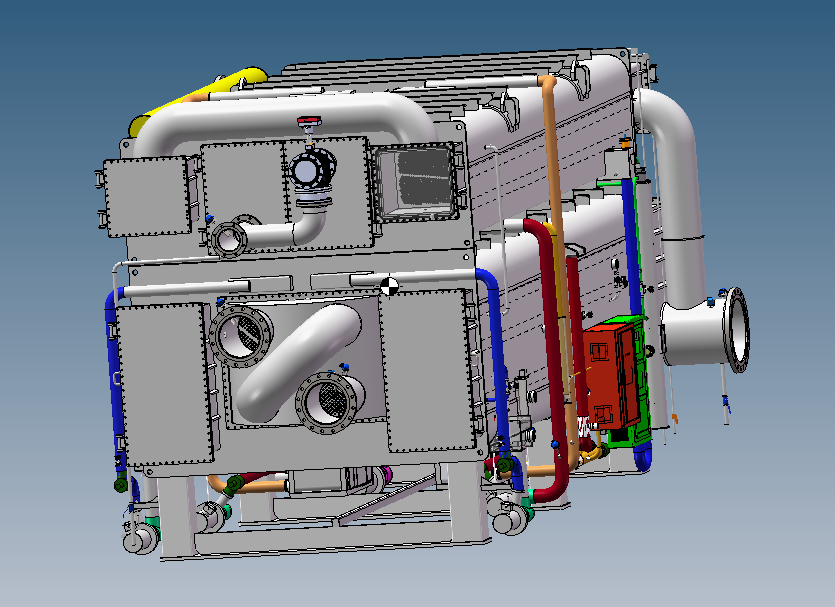

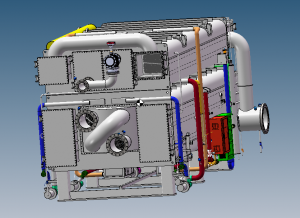

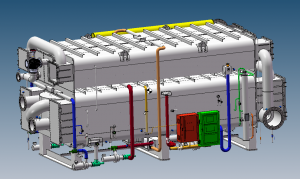

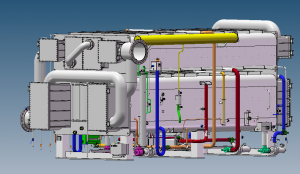

Double stage hot water absorption chiller

2.1 Working Principle

The dilute solution in absorber is pumped by the solution pump, heated in the heat exchanger, and then enters the generator. Within the generator, the dilute solution is heated to boiling by the working hot water, producing refrigerant steam while the solution is concentrated into a concentrated solution.

The refrigerant steam generated in the generator is cooled by cooling water, condensing into refrigerant water through U-type pipes into the evaporator water plate.

Due to the low pressure in the evaporator, refrigerant water is pumped by refrigerant pump and sprayed onto the evaporator tube. It absorbs heat from the cooling water, evaporating and thereby lowering the temperature of the cooling water in the tube to achieve refrigeration.

The concentrated solution from generator flows through a heat exchanger into the absorber, where it drips onto the absorber tube. Cooled by the circulating cooling water within the tubes, to absorb refrigerant steam from the evaporator and become a dilute solution. Thus, the concentrated solution continuously absorbs refrigerant steam generated by the evaporator, sustaining the evaporation process within the evaporator. The diluted solution, having absorbed the refrigerant steam, is pumped back to the generator for reconcentration. This completes one refrigeration cycle. Through continuous repetition of this process, the evaporator continuously outputs low-temperature chilled water for air conditioning or industrial cooling applications.

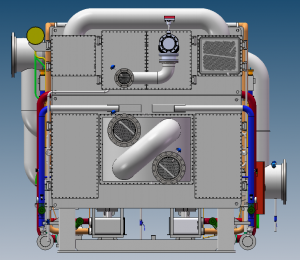

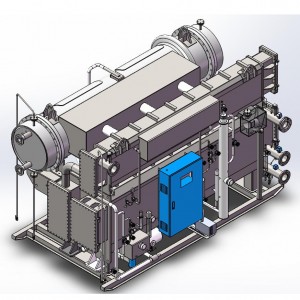

The double-stage hot water unit comprises two generators, two condensers, two evaporators, and two absorbers. The solution flows in series through the upper generator, lower generator, upper absorber, and lower absorber. Hot water flows countercurrently with chilled water and cooling water, creating countercurrent heat exchange.

By rationally distributing refrigeration capacity throughout the cycle, optimizing temperature differentials, and selecting appropriate temperature, pressure, and concentration parameters, the generation, condensation, evaporation, and absorption processes achieve ideal conditions. This enables the hot water heat source to be cooled to a lower temperature.

The aforesaid cycle occurs repeatedly to form a continuous heating process (Fig. 1-1).

2.2 Process Flow Diagram

2.3 Main Components and Functions

1.Generator

Generation Function: The generator is the power source of the chiller. The heat source enters the generator and heats the diluted LiBr solution. Water in the diluted solution evaporates in the form of refrigerant steam and enters the condenser. Meanwhile, the diluted solution concentrates into a concentrated solution.

Featuring a shell-and-tube structure, the generator comprises the heat transfer tube, tube sheet, support plate, shell, steam box, water chamber and baffle plate. As the highest-pressure vessel inside the heat pump system, the generator has an internal vacuum approximate to zero (a micro negative-pressure).

2. Condenser

Condenser Function: The condenser is a heat generation unit. refrigerant steam from the generator enters the condenser and heats the DHW to a higher temperature. Then the heating effect is achieved. After refrigerant steam heats the DHW, it condenses in the form of refrigerant steam and enters the evaporator.

Featuring a shell-and-tube structure, the condenser comprises the heat transfer tube, tube sheet, support plate, shell, water storage tank and water chamber. Normally, the condenser and the generator are interconnected directly by pipes, so they have basically the same pressure.

3. Evaporator

Evaporator Function: The evaporator is a waste heat recovery unit. Refrigerant water from the condenser evaporates from the surface of the heat transfer tube, taking away the heat of and cools down the CHW inside the tube. Thus waste heat is recovered. refrigerant steam evaporating from the surface of the heat transfer tube enters the absorber.

Featuring a shell-and-tube structure, the evaporator comprises the heat transfer tube, tube sheet, support plate, shell, baffle plate, drip tray, sprinkler and water chamber. The working pressure of the evaporator is around 1/10 of the generator pressure.

4. Absorber

Absorber Function: The absorber is a heat generation unit. Refrigerant steam from the evaporator enters the absorber, where it is absorbed by the concentrated solution. The concentrated solution turns into a diluted solution, which is pump delivered into the next cycle. While the refrigerant steam is being absorbed by the concentrated solution, huge quantities of heat absorbed are produced and heat the DHW to a higher temperature. Thus the heating effect is achieved.

Featuring a shell-and-tube structure, the absorber comprises the heat transfer tube, tube sheet, support plate, shell, purging pipe, sprayer and water chamber. The absorber is the lowest-pressure vessel inside the heat pump system and is under the greatest impact from non-condensable air.

5. Heat Exchanger

Heat Exchanger Function: The heat exchanger is a waste heat recovery unit used to recover the heat in the LiBr solution. Heat in the concentrated solution is transferred by the heat exchanger to the diluted solution for thermal efficiency improvement.

Featuring a plate structure, the heat exchanger has a high thermal efficiency and a notable energy saving effect.

6. Automatic Air Purge System

System Function: The air purge system is ready to pump out the non-condensable air in the heat pump and maintain a high vacuum condition. During operation, the diluted solution flows at a high rate to produce a local low pressure zone around the ejector nozzle. Thus the non-condensable air is pumped out of the heat pump. The system operates simultaneously with the heat pump. While the heat pump is working, the automatic system helps maintain a high vacuum inside and ensure system performance and a maximized service life.

The air purge system is a system composed of the ejector, cooler, oil trap, air cylinder and valve.

7. Solution Pump

The solution pump is used to deliver the LiBr solution and secure the normal flow of liquid working mediums inside the heat pump.

The solution pump is a wholly-enclosed, canned centrifugal pump featuring zero liquid leakage, low noise, high explosion-proof performance, minimal maintenance and a long service life.

8. Refrigerant Pump

The refrigerant pump is used to deliver refrigerant water and ensure the normal spray of refrigerant water on the evaporator.

The refrigerant pump is a wholly-enclosed, canned centrifugal pump featuring zero liquid leakage, low noise, high explosion-proof performance, minimal maintenance and a long service life.

9. Vacuum Pump

The vacuum pump is used for vacuum purging at the start-up stage and air purging at the operation stage.

The vacuum pump features a rotary vane wheel. The button to its performance is vacuum oil management. The prevention of oil emulsification has an obviously positive impact on air purging performance and helps lengthen the service life.

10. Electric Cabinet

As the control center of the LiBr heat pump, the electrical cabinet houses the main controls and electrical components.

Waste Heat Recovery. Energy Conservation&Emission Reduction

It can be applied to recover LT waste hot water or LP steam in thermal power generation, oil drilling, petrochemical field, steel engineering, chemical processing field, etc. It can utilize river water, groundwater or other natural water source, converting LT hot water into HT hot water for the purpose of district heating or process heating.

Dual effect (Used for Cooling/Heating)

Driven by natural gas or steam, dual effect absorption heat pump can recover waste heat with very high efficiency (COP can reach 2.4). It is equipped with both heating and cooling function, especially applicable to concurrent heating/cooling demand.

Two Phase Absorption&Higher Temperature

Class II two phase absorption heat pump can improve waste hot water temperature to 80°C without other heat source.

Intelligent Control&Easy Operation

Fully automatic control, it can realize one-button On/Off, load regulation, solution concentration limit control and remote monitoring.

Artificial Intelligent Control System AI (V5.0)

■Fully-automatic control functions

The control system (AI, V5.0) is featured by powerful and complete functions, such as one-key start up/shutdown, timing on/off, mature safety protection system, multiple automatic adjustment, system interlock, expert system, human machine dialogue(multi languages), building automation interfaces, etc.

■Complete unit abnormality self-diagnosis and protection function

The control system (AI, V5.0) features 34 abnormality self-diagnosis&protection functions. Automatic steps will be taken by system according to level of an abnormality. This is intended to prevent accidents, minimize human labor and ensures a sustained, safe and stable operation of chiller.

■Unique load adjustment function

The control system (AI, V5.0) has a unique load adjustment function, which enables automatic adjustment of chiller output according to actual load. This function not only helps to reduce startup/shutdown time and dilution time, but also contributes to less idle work and energy consumption.

■Unique solution circulation volume control technology

The control system (AI, V5.0) employs an innovative ternary control technology to adjust solution circulation volume. Traditionally, only parameters of generator liquid level are used to control of solution circulation volume. This new technology combines merits of concentration&temperature of concentrated solution and liquid level in generator. Meanwhile, an advanced frequency-variable control technology is applied to solution pump to enable unit to achieve an optimal circulated solution volume. This technology improves operating efficiency and reduces startup time and energy consumption.

■Solution concentration control technology

The control system (AI, V5.0) uses a unique concentration control technology to enable real-time monitoring/control of concentration and volume of concentrated solution as well as hot water volume. This system can maintain chiller under safe and stable at high-concentration condition, improve chiller operating efficiency and prevent crystallization.

■Intelligent automatic air purge function

The control system (AI, V5.0) can realize real-time monitoring of vacuum condition and purge out the non-condensable air automatically.

■Unique dilution stop control

This control system (AI, V5.0) can control operation time of different pumps required for dilution operation according to concentrated solution concentration, ambient temperature and remaining refrigerant water volume. Therefore, an optimal concentration can be maintained for the chiller after shutdown. Crystallization is precluded and chiller re-start time is shortened.

■Working parameter management system

Through interface of this control system (AI, V5.0), operator can perform any of following operations for 12 critical parameters relating to chiller performance: real-time display, correction, setting. Records can be kept for historical operation events.

■Unit fault management system

If any prompt of occasional fault is displayed on operation interface, this control system(AI, V5.0) can locate and detail fault, propose a solution or trouble shooting guidance. Classification and statistical analyses of historical faults can be conducted to facilitate maintenance service provided by operators.