Why is the Rupture Disk Indispensable?

As a pioneer , Hope Deepblue consistently places safety at the core of LiBr absorption chiller designs. We deeply understand how each component contributes to ensuring long-term, reliable operation.

Sources of Pressure in the Unit

LiBr absorption chiller operate in a high-vacuum environment. However, certain abnormal conditions can compromise this vacuum. For example, an excessively high driving heat source temperature may cause pressure in components like the generator to rise sharply, as accumulated heat cannot be dissipated in time. Similarly, if heat exchange tubes become damaged due to corrosion or excess moisture, internal pressure may increase. Such abnormal pressure conditions threaten operational safety. In Hope Deepblue LiBr absorption chiller, multi-level monitoring systems provide real-time alerts for these risks, while the rupture disk acts as the ultimate safety barrier.

How the Rupture Disk Works

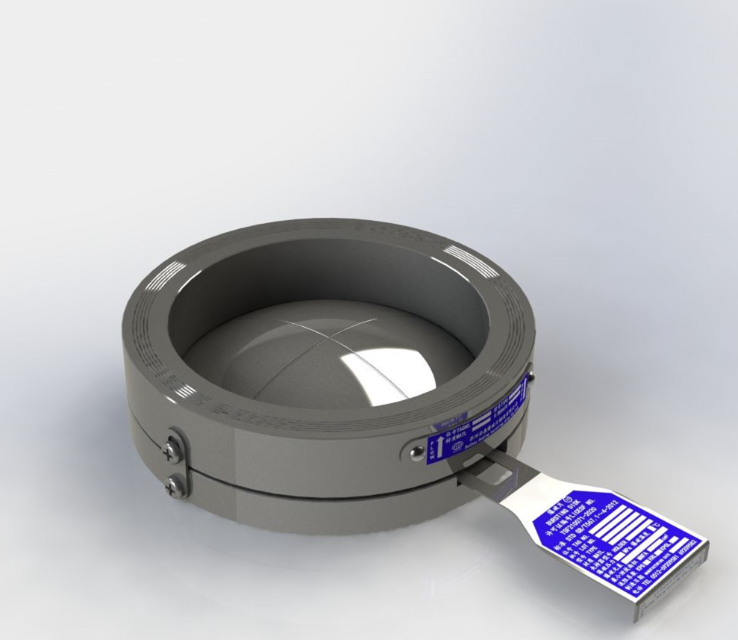

A rupture disk is a non-reclosing pressure relief device. Its working principle is based on a precisely designed weak point. This specially engineered metal membrane is calibrated to remain intact within the normal operating pressure range (including vacuum). However, when pressure exceeds a predefined threshold, the disk instantly ruptures, creating an immediate venting path. Since it functions through controlled failure, the rupture disk is a single-use component and must be replaced after activation.

Key Safety Functions

The rupture disk serves as a critical and final line of defense. Its primary purpose is overpressure relief. If other control or safety devices (e.g., temperature or pressure sensors) fail to respond in time, the rupture disk sacrifices itself to rapidly discharge dangerous pressure levels. This helps:

- Prevent permanent deformation or rupture of the main vessel, avoiding severe equipment damage.

- Protect personnel safety by directing pressure release and reducing the risk of sudden vessel failure.

In summary, the rupture disk acts as a dedicated "safety sentinel." Its one-time activation safeguards the unit's structural integrity and protects users, making it an indispensable safety

Post time: Oct-24-2025