Cause of Damage of Condensate Heat Exchange Plate

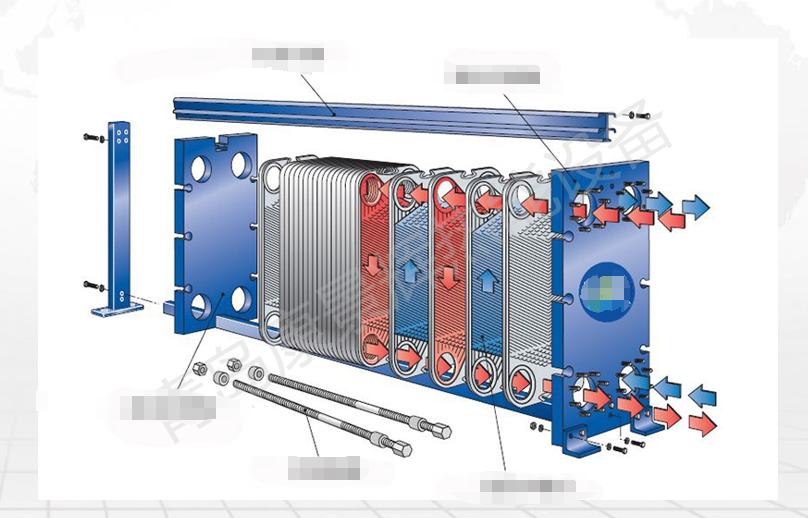

Hope Deepblue is the largest manufacturer of refrigeration and heating equipment in Southwest China, specializing in LiBr absorption chillers and heat pumps. These units are designed for cooling using waste heat, and they function as large-scale heat exchange systems. Within these larger heat exchange units, there are numerous smaller heat exchangers, including plate heat exchangers, which play a crucial role in optimizing heat transfer efficiency.

In the course of long-term operation of the unit, these heat exchangers will inevitably wear out due to the generation of water hammer, especially in steam LiBr absorption chillers.

The following are the causes of water hammer:

- Water Pressure Impact: When the valve of the condensate system in a steam LiBr absorption chiller is quickly opened, it can cause a rapid increase or decrease in pressure within the system, leading to water hammer.

- Flow Impact: When steam and water meet, especially at corners in the heat exchanger plates, the resulting interaction can create conditions prone to water hammer, causing impact on the plates.

- Differential Pressure Impact: A high steam flow rate combined with a low water flow rate can create a pressure differential between the two, which in turn generates an impact on the heat exchange plates, contributing to water hammer.

Hope Deepblue carefully analyzes the causes of plate exchanger wear and, through technical adjustments, enhances the durability of the plate exchangers in our units. By implementing these improvements, we ensure that the plate exchangers have a longer lifespan, providing our customers with more reliable and efficient products.

Post time: Mar-15-2024