BaoTou Steel Group BaoShan Thermal Station

Waste Heat Recovery (EMC) Project

Project location: Baiyun Ebo Baotou Steel BaoShan Mining Company Thermal Station

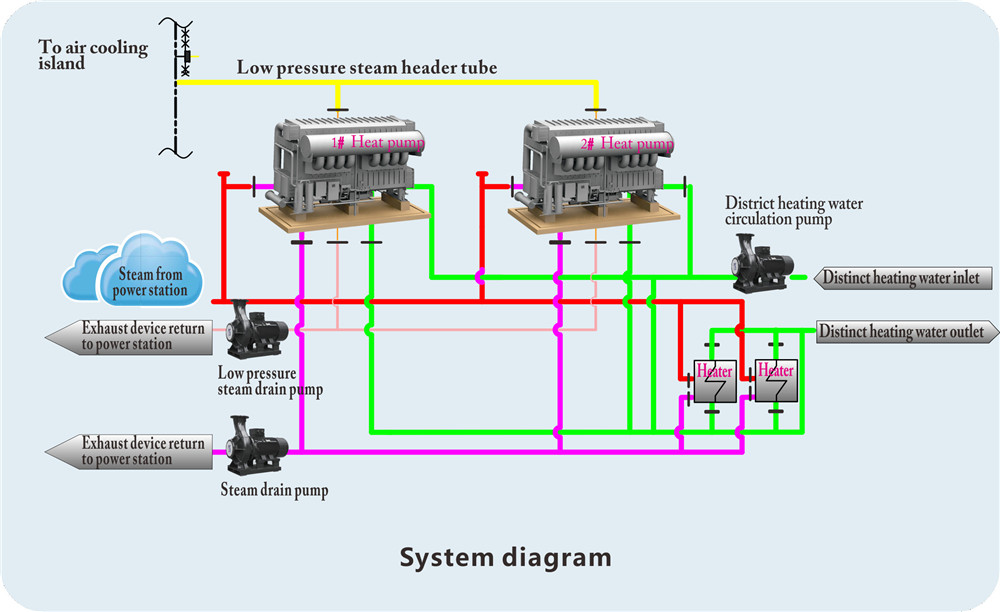

Equipment selection: 2 unit 42.7MW steam LiBr absorption heat pump

Main function: District heating

General introduction

The thermal power station of Baoshan Mining Company of Bao Steel is equipped with two low pressure steam heat pump units. The steam extraction of the steam turbine is used as the driving heat source to recover the waste heat from exhaust steam condensation of the steam turbine and raise the district heat water return to 77.9°C.Then it entered the first heating station to further increase the heat district heat water temperature to 85°C, which was used for the heating supply of Baoshan and Barun Mining Company, replacing the Barun hot water boiler house.

Technical Data

Heating capacity: 42.7MW/unit

Driven steam pressure: 0.4-0.6MPa(G)

Qty: 2 unit

COP: >1.8

District heating water: 77.9/60°C

Dimension: 10000*4720*5750mm

Low pressure steam: 15kPa (A)

Operation weight: 108t/unit

Steam consumption: 27.87t/h

Efficiency

The two 42.7MW heat pump units installed at the facility are highly efficient in recovering 36MW of waste heat from steam. This results in a significant reduction in the need for steam, with 60.2 tons per hour of steam consumption being saved compared to the traditional boiler heating system.

When considering a 7-month heating cycle, the heat pump system is projected to save approximately 303,448 tons of steam annually. This translates to energy savings of about 30,000 tons of standard coal per year. Additionally, the system’s efficiency leads to a substantial reduction in carbon dioxide emissions by 7.96 tons annually.

The implementation of this heat pump heating system brings both economic and social benefits:

- Economic benefits: The savings in steam and coal directly lower operational costs and improve the overall efficiency of the facility.

- Social benefits: The reduction in CO2 emissions supports environmental sustainability efforts and contributes to cleaner energy use in the region, aligning with global efforts to mitigate climate change.

These results demonstrate how waste heat recovery systems can provide significant environmental and financial advantages while enhancing overall system performance.

Web: https://www.deepbluechiller.com/

E-Mail: yut@dlhope.com / young@dlhope.com

Mob: +86 15882434819/+86 15680009866

Post time: Mar-31-2023