Products

Fully Premixed Extra Low NOx Vacuum Water Boiler

“Vacuum Water Boiler” is a heating equipment with heat medium water as the intermediate medium: utilizing the evaporation and condensation process of the heat medium water to absorb the heat from the fuel (Exhaust or other heat source) to heat the hot water and deliver it to the terminal. It’s commonly known as: vacuum boiler or vacuum phase change boiler.

At atmospheric pressure (one atmospheric pressure ), the boiling point of the water is 100℃, the working temperature of heat medium water of “Vacuum Water Boiler” should be less than 97℃, the corresponding pressure of 0.9 atmospheres, lower than the atmospheric pressure, so the “Vacuum Water Boiler” is a kind of intrinsically safe heating equipment without the risk of explosion.

“Fully Premixed Extra Low NOx Vacuum Water Boiler” utilizes “Hope Deepblue Micro Flame Low Temperature Combustion Technology” to upgrade and iterate the “Vacuum Water Boiler”, which reduces the product and operating costs and improves the efficiency of the unit under the premise of ensuring safety.

The common fuel of “Fully Premixed Extra Low NOx Vacuum Water Boiler” is natural gas. Its combustion exhaust contains a large amount of vapor, that’s why Deepblue’s vacuum boiler is standard equipped with exhaust condenser, which is used to recover the latent heat of vaporization of steam in exhaust, and the comprehensive thermal efficiency can be increased to 104% in extreme limit.

The Formation and Harm of Nitrogen Oxide NOx

During the combustion process of Exhaust, it produces nitrogen oxides, the main components of which are nitric oxide (NO) and nitrogen dioxide (NO2), collectively known as NOx. NO is colorless and odorless gas, insoluble in water. It accounts for more than 90% of all NOx formed during high temperature combustion, and is not highly toxic or irritating when its concentration ranges from 10-50 PPm. NO2 is brownish-red gas that is visible even at low concentrations and has a distinctive acidic odor. It is strongly corrosive and can irritate the nasal membranes and eyes at concentrations of nearly 10 ppm even only remaining a few mins in the air, and it can cause bronchitis at concentrations of up to 150 ppm and pulmonary edema at concentrations of up to 500 ppm.

NOx and O2 can be oxidized by photochemical reactions to form NO2. NOx reacts with water vapor in the air to form acid rain under special circumstances. NOx and hydrocarbons in automobile exhaust are irradiated by ultraviolet rays from the sun to form photochemical smog that is harmful to humans. So in order to protect the environment and human health, we need to reduce NOx emissions.

Formation Mechanism of NOx During Combustion

1. Thermodynamic type NOx

Nitrogen in the combustion air is oxidized at high temperatures (T > 1500 K) and high oxygen concentrations. Most gaseous fuels (e.g. natural gas and LPG) and general fuels that do not contain nitrogen compounds produce NOx in this way. Thermal NOx in the Exhaust increases dramatically when flame temperatures is above 1200℃. This is the main control item for NOx low-NOx combustion.

2. Instant type NOx

Formed in the flame region by the interaction of hydrocarbons (CHi radicals) formed with nitrogen in the combustion air. This method of forming NOx is very fast. This NOx can only be produced when the oxygen concentration is relatively low. And therefore, it’s not a significant source in gas combustion.

3. Fuel type NOx

The production of fuel-based NOx depends on the nitrogen contained in the fuel. When the nitrogen content of the fuel exceeds 0.1%, the production is already considerable, especially for liquid and solid fuels. The use of natural gas and LPG does not produce this type of NOx.

Hope Deepblue Micro Flame Low Temperature Burn Technology

1. Flame cutting, fractional combustion: miniaturization of flames reduces the initial energy of individual flames and lowers flame temperature to radically reduce thermal NOx generation.

2. Microporous jet flame: Physical method to eliminate tempering and ensure system safety.

3. Variable frequency electronic proportional regulation: precise control of oxygen content, eliminating instantaneous NOx, while ensuring efficient combustion and emission compliance at full load.

Safe

Vacuum phase change heat transfer: no explosion risk, no need for inspection, no installation location restriction, no need for professional operators.

Reliable internal circulation water quality: fill with soft water or desalted water , no scaling and corrosion risk, long service life.

Multiple security protection: power supply, gas, air, heat medium water, hot water and other 20 protection measures.

Full water-cooled film furnace: according to the pressure boiler standard, greater resistance to deflagration and sudden load changes.

Advanced

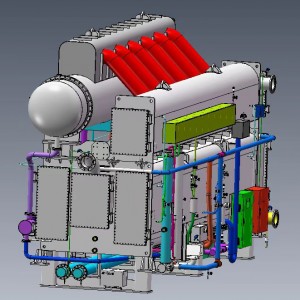

Integral modular design: reasonable layout, compact structure, beautiful appearance.

CFD numerical simulation: control flame temperature and exhaust flow field.

Low emission: flame cutting, micro flame low temperature burn technology, the NOx emission of the full load is less than 20mg/m³.

Unique intelligent control system: simple operation, customized function.

Global remote operation and maintenance system: global remote expert system, monitor and manage the operation status of the unit, fault prediction and processing.

Efficient

Vacuum phase change heat transfer: high heat transfer efficiency, internal circulating water in a closed cycle, no need to be replaced.

Full water-cooled film furnace: low surface temperature, low heat dissipation.

Operation status real time monitoring: monitor the operation status of fuel, boiler body and hot water, intelligent adjustment of load adaptation to reduce ineffective energy consumption.

High thermal efficiency: thermal efficiency 97~104% (related to hot water return temperature).