Products

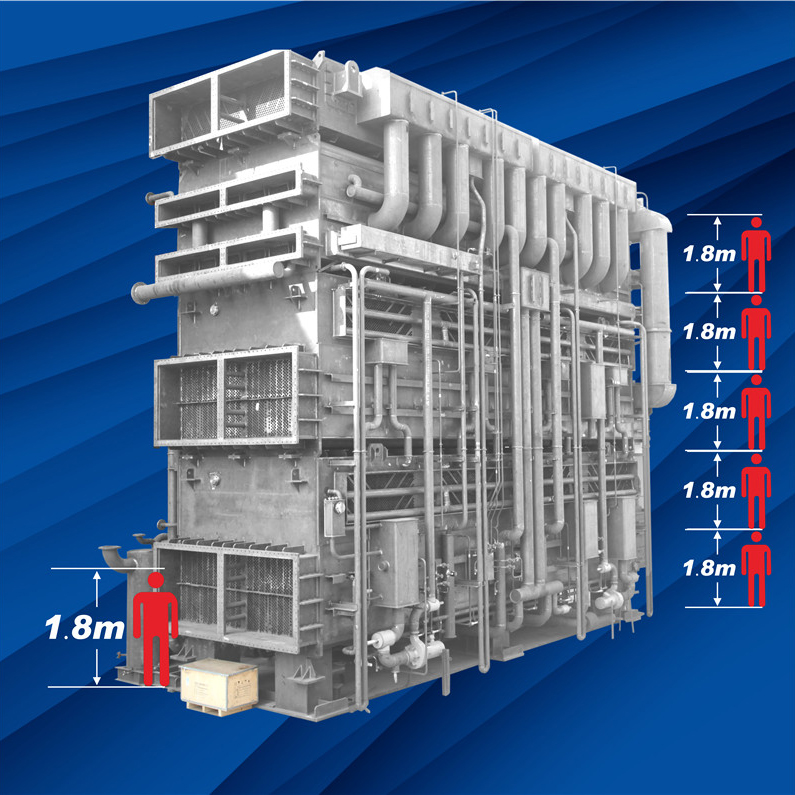

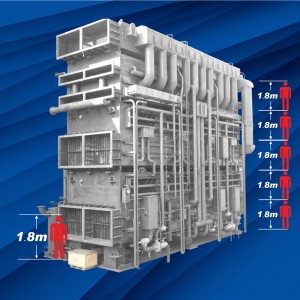

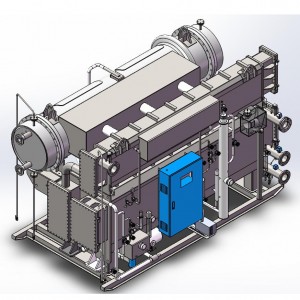

Low Pressure Steam Absorption Heat Pump

This innovative heating unit uses thermal energy from sources such as steam, DHW or natural gas to power its lithium bromide based heat exchange system, providing an efficient and cost effective way to provide warmth and comfort to any residential or commercial property.

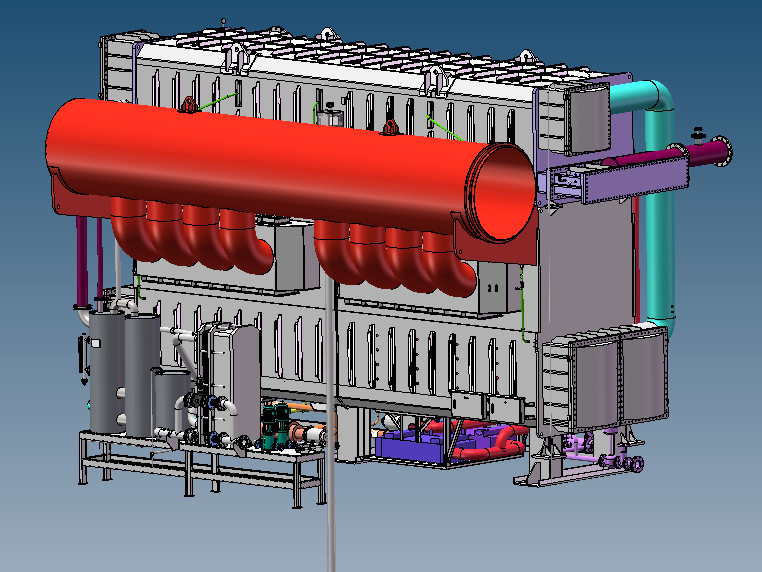

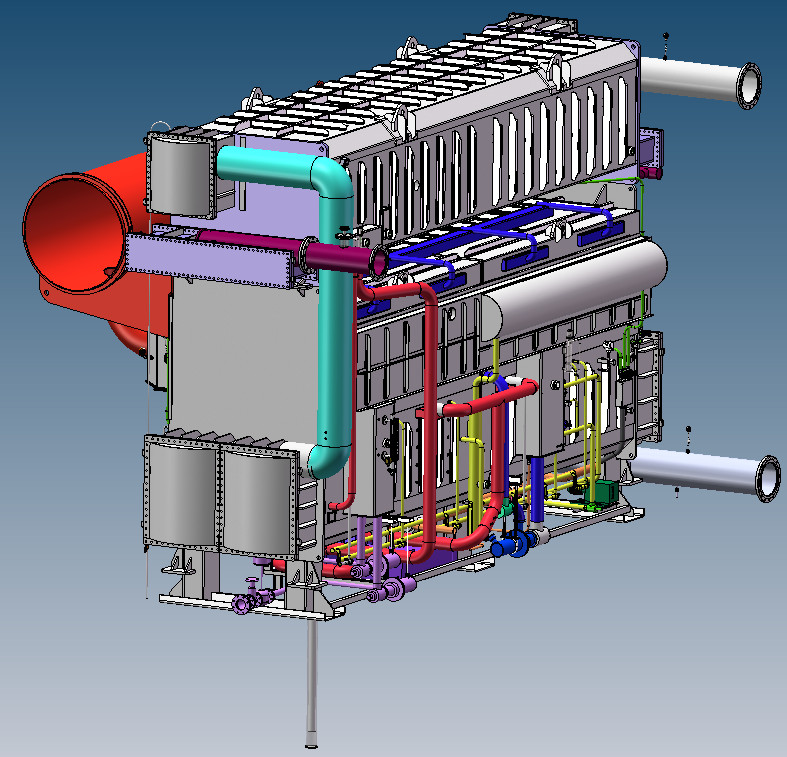

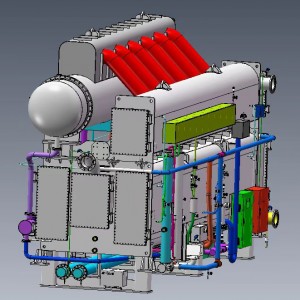

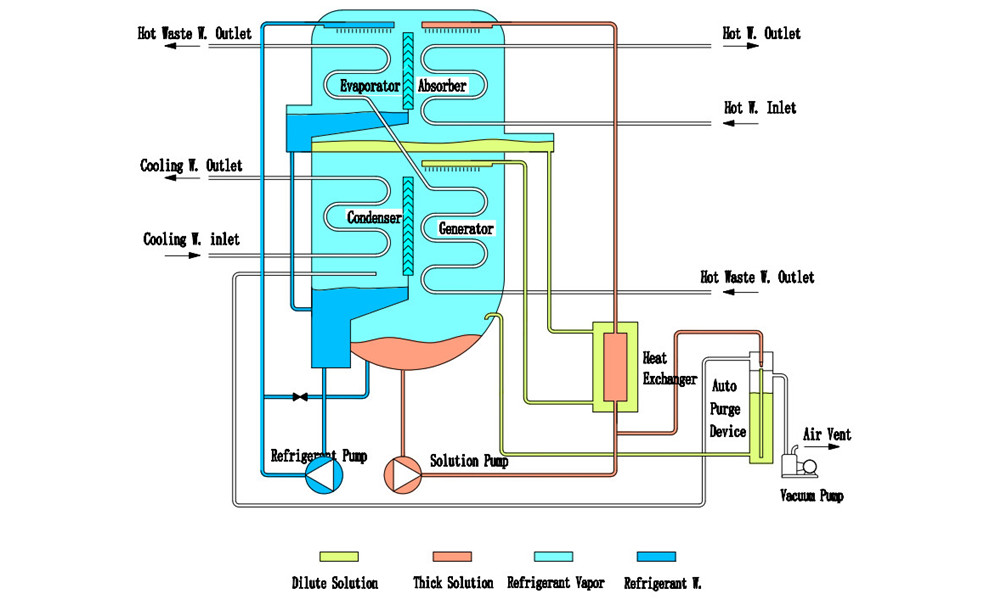

The core of the low pressure steam absorption heat pump is its advanced working principle, which relies on the evaporation of refrigerant water in the evaporator to generate steam, which is then absorbed by the concentrated lithium bromide solution in the absorber. This absorption process releases heat, which then heats the DHW to a higher temperature, producing the desired heating effect. The diluted LiBr solution is then pumped to a heat exchanger where it is heated and sent to a generator where it is converted to refrigerant vapor which again heats the DHW in the condenser. The cycle then continues, with concentrated lithium bromide solution being released from the generator, cooled in a heat exchanger, and then pumped back to the absorber, which again absorbs refrigerant vapor from the evaporator.

Due to its unique design, a key advantage of the low pressure steam absorption heat pump is its ability to fully utilize the waste heat from the DHW. The evaporator and absorber are designed as upper and lower parts, respectively, which help to reduce the concentration of dilute solution at the outlet of the absorber, increase the concentration difference between the inlet and outlet of the generator, and ultimately improve the performance of the unit. But perhaps most importantly, low pressure heat pumps are an environmentally friendly and energy-efficient solution that can help you save money while reducing your carbon footprint.

By using thermal energy from natural or man-made sources, it reduces the need for traditional fuels, which can be expensive and harmful to the environment.

Plus, it runs quietly and produces no harmful emissions, making it the perfect choice for those looking to reduce their impact on the planet.

So, if you are interested in an efficient, reliable and environmentally friendly heating solution, low pressure steam absorption heat pumps are the right choice for you. With its innovative design and state-of-the-art technology, it is a cost-effective and sustainable way to heat your home or business while reducing your carbon footprint and protecting the environment for future generations.

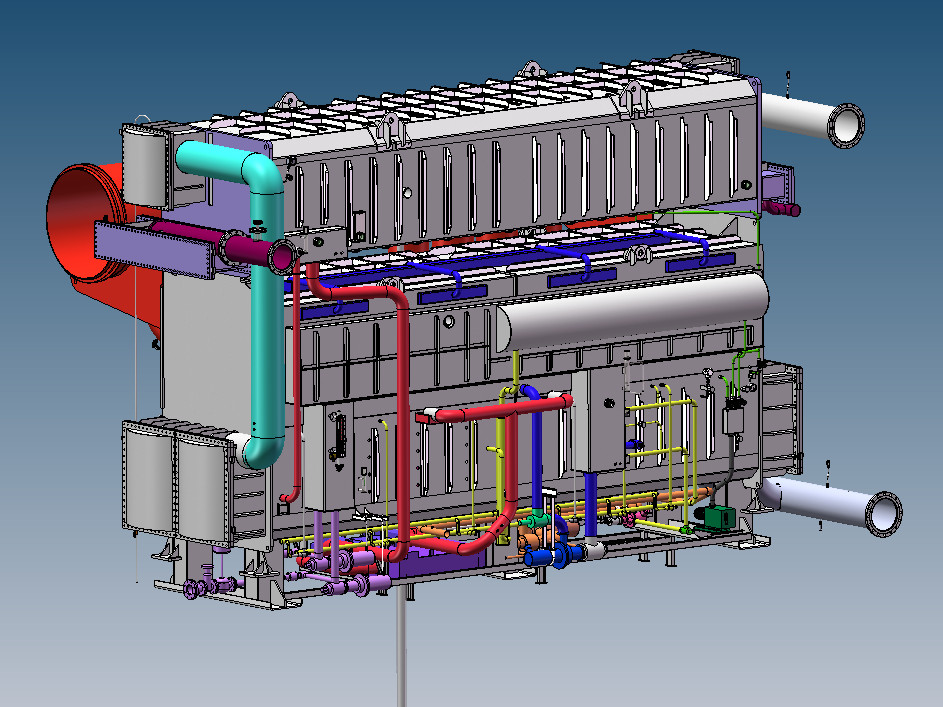

Process Flow Diagram

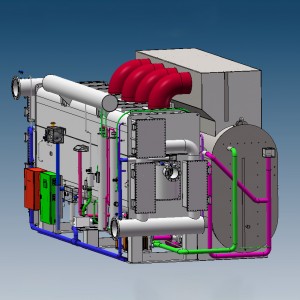

The control system (AI, V5.0) has complete low pressure steam absorption heat pump abnormality self-diagnosis and protection functions, and the unique 34 functions ensure the safety and reliability of the system. By taking automated steps, it helps to prevent accidents, reduce labor, and ensure that the chiller operates in a stable manner.

The unique load adjustment function of this control system (AI, V5.0) can automatically adjust the chiller output according to the actual load. This not only reduces startup/shutdown times and dilution times, but also reduces idle work and energy consumption.

The system's unique solution circulation volume control technology is innovative, using ternary control technology to adjust the solution circulation volume. The advanced frequency conversion control technology enables the machine to achieve the optimal circulating solution volume, thereby reducing start-up time and energy consumption.

The solution concentration control technology of AI V5.0 can monitor/control the concentration and volume of the concentrated solution and the amount of hot water in real time. Provide chillers with safe and stable operation under high concentration conditions, improve the operating efficiency of chillers, and prevent crystallization. The control system (AI, V5.0) has an intelligent automatic purging function, real-time monitoring of the vacuum state, and automatic purging of non-condensable air.

The system's unique dilution stop control can manage the running time of different pumps required for dilution operation according to concentrated solution concentration, ambient temperature and remaining refrigerant water volume. Therefore, the optimal concentration can be maintained after the chiller is shut down, the crystallization can be avoided, and the restart time of the chiller can be shortened.

In addition, the working parameter management system is an interface through which the operator can perform any of the following operations on the 12 key parameters related to the performance of the chiller: real-time display, correction and setting. A record of historical operational events can be kept. The unit fault management system can also locate and refine the occasional fault prompts displayed on the operation interface, and provide solutions or troubleshooting guidance.

The classification and statistical analysis of historical faults can be carried out, which is convenient for operators to provide maintenance services. In conclusion, whether you need a chiller or absorption heat pump control system for a small residential property or a large commercial property, the AI V5.0 is undoubtedly the ultimate fully automatic control system you should choose. Its powerful features, combined with its safety and reliability, make it the perfect product for investment.